SOLUTIONS FOR E-MOBILITY.

For smooth support in the mobility transition.

New technologies need new ideas and modern execution. Our unique tool solutions support you in solving challenges during the development of new components. Put your trust in our specialists in synchronous and conventional machining applications and benefit from our advice!

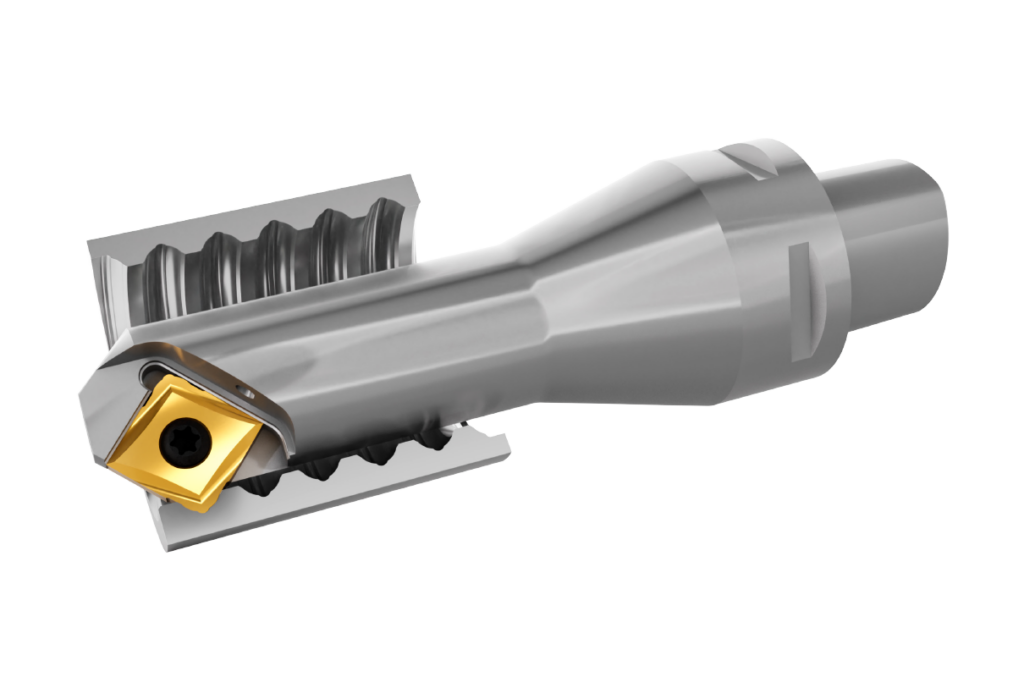

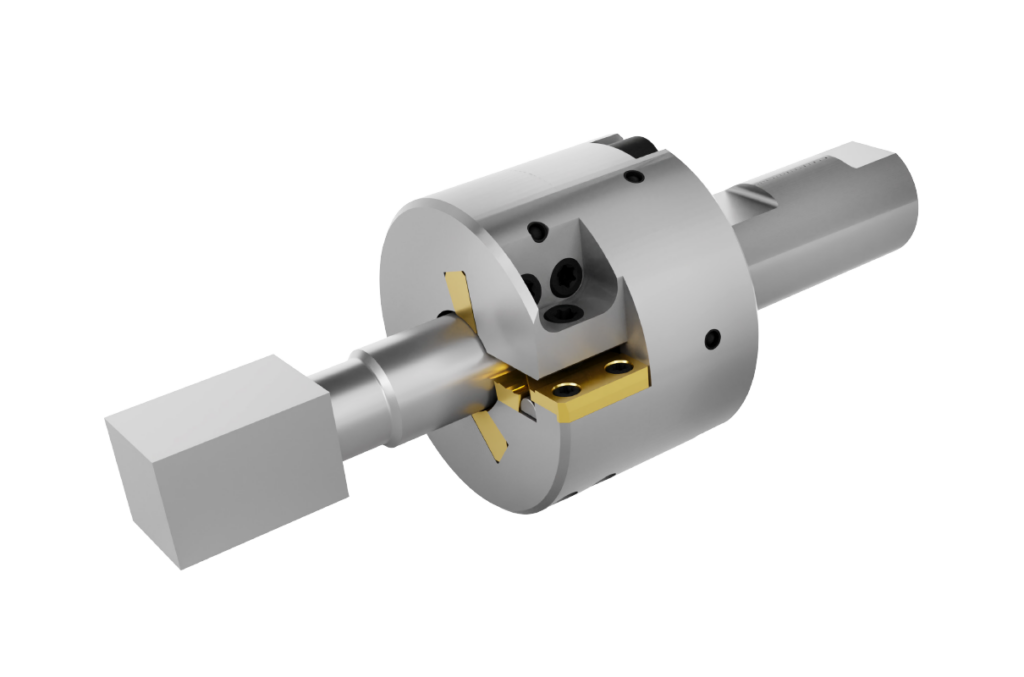

Thread-turning tool

When turning ball screws for steering nuts, the most precise tools are required. Combining our indexable inserts with our carrier tools is a guarantee for the very highest level of precision. We can also offer a vibration-absorbing version of the carrier tool if needed.

Discover the turning process type.

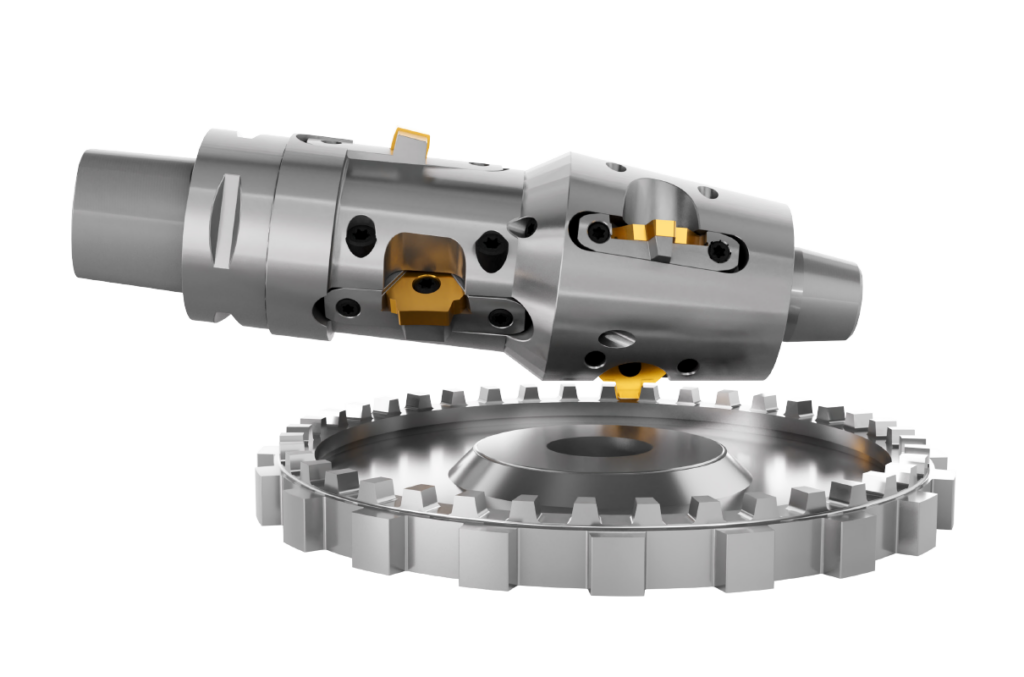

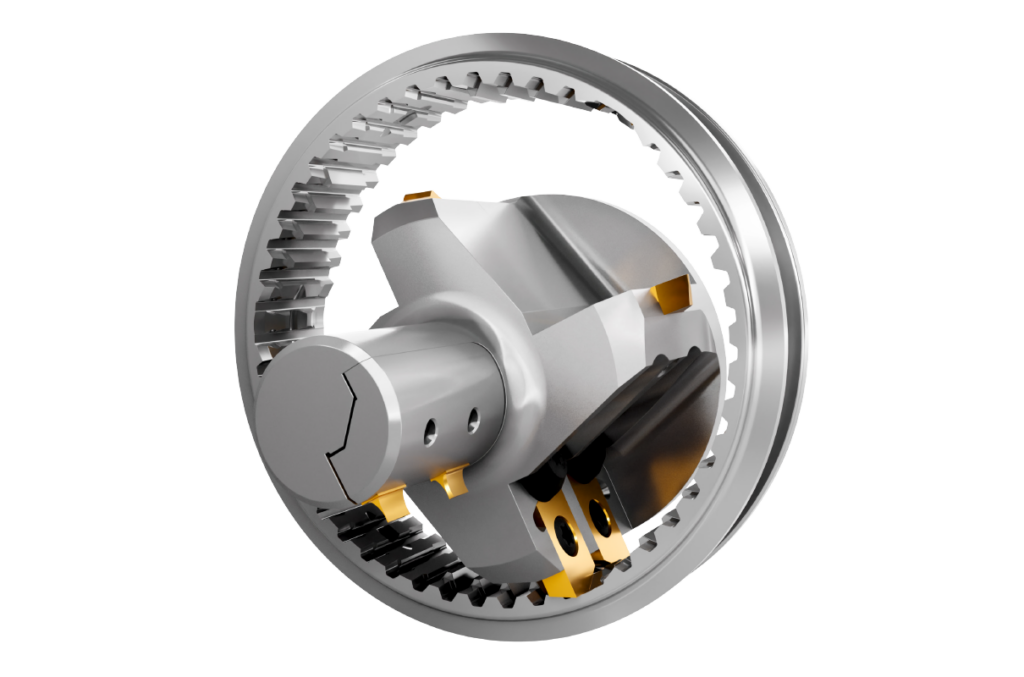

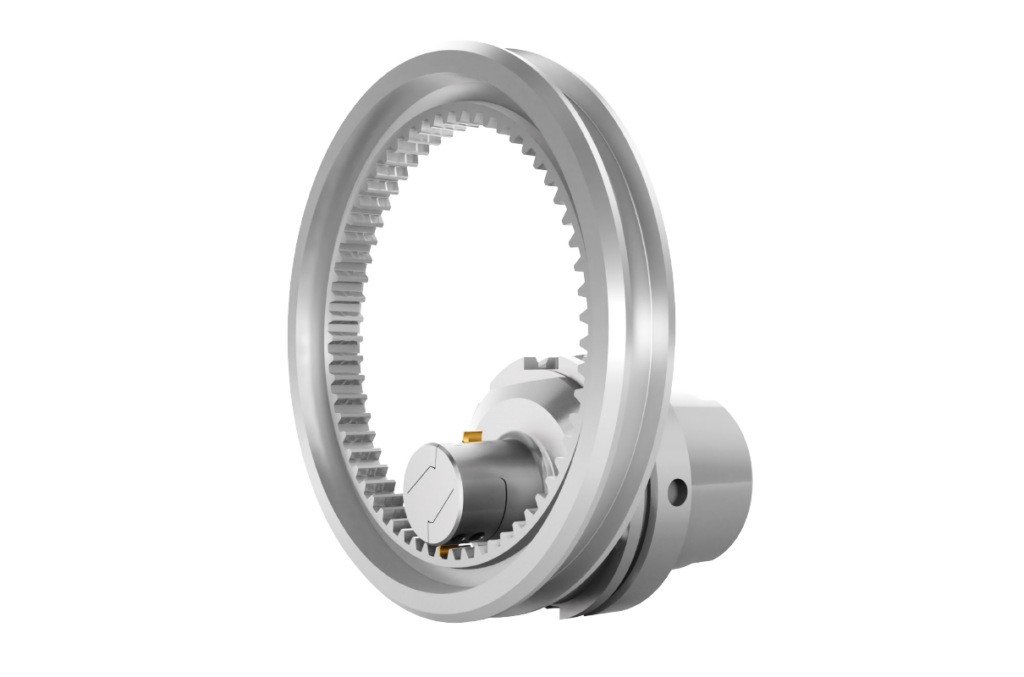

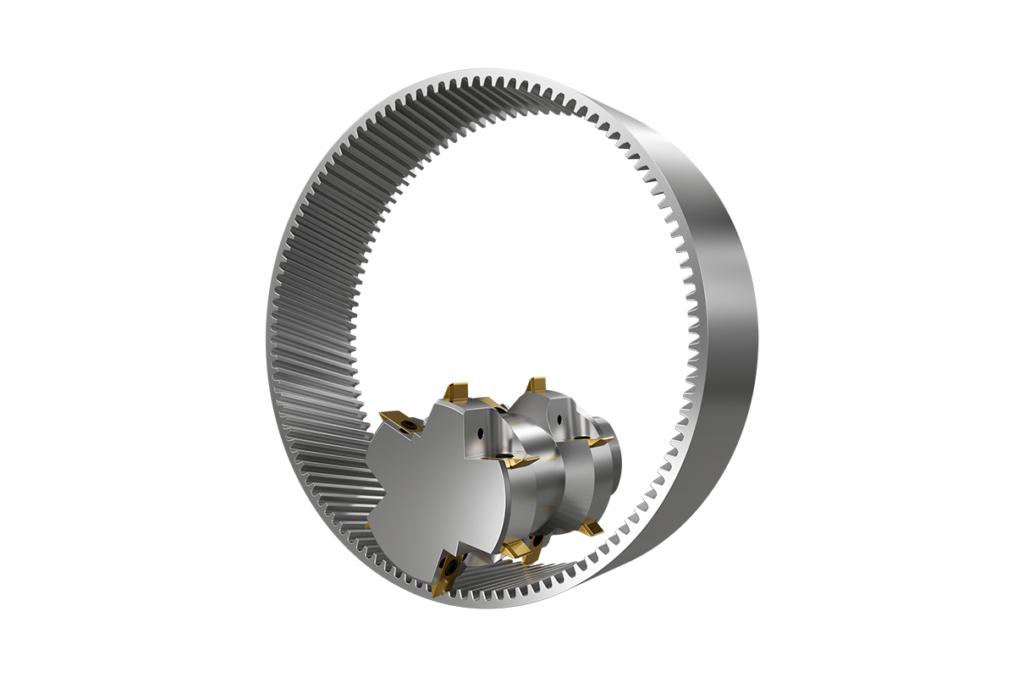

Impact tooth combi-tool

An example of the optimum solution for face and circumferential gearing. The circumferential gearing works with two pre-cutters and one finishing cutter. The undercut face gearing sensor in the tool is processed by two finishing cutters. All milling cassettes can be adjusted both axially and radially.

Discover the face and circumferential gearing process type.

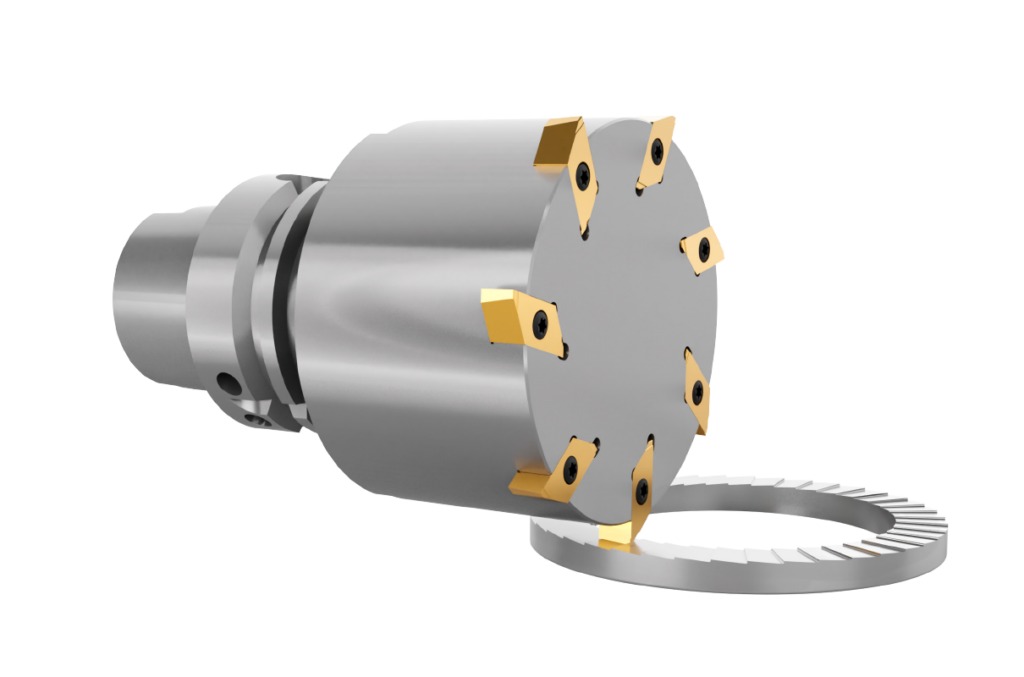

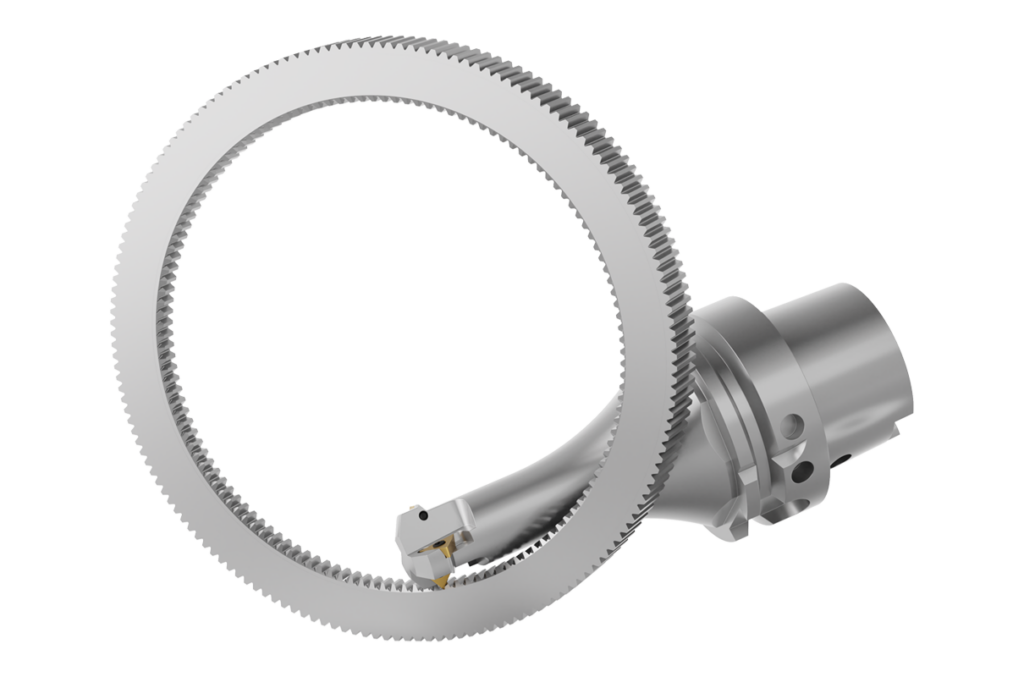

Face gearing tool

Our tools can also rotatively produce face gearing on machining centers with synchronized axes – economically and highly efficiently, of course. The use of 7 finishing cutters significantly reduces the cycle time for this form of processing. Even with very intricate workpieces, we can guarantee maximum precision with our solutions.

Discover the face gearing process type.

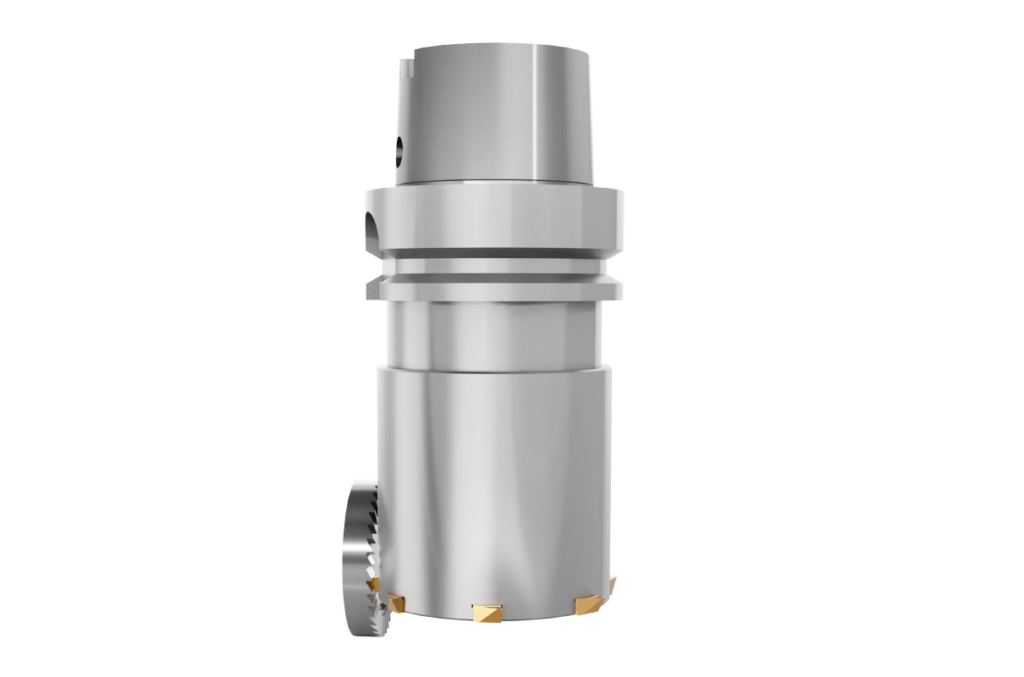

Face gearing tool

To meet the challenge of achieving highly efficient production of toothing on serrated washers, we have designed and produced a synchronous rotative tool with 7 cutting edges. The special feature with these components is that they have an undercut and low tooth geometry depth.

Discover the face gearing process type.

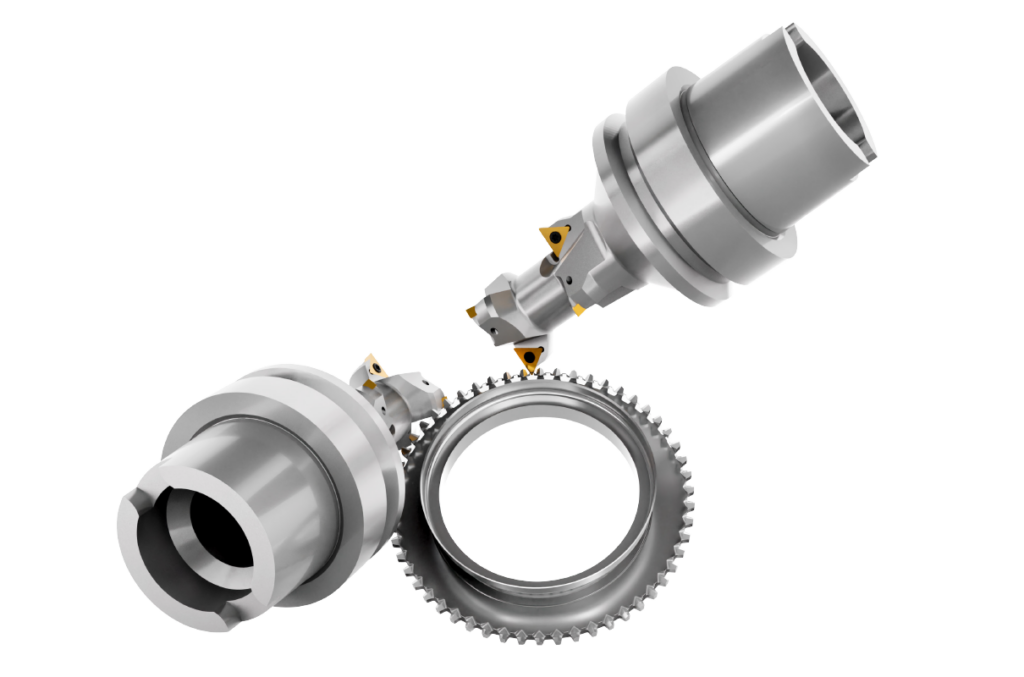

Sliding sleeve production combi-tool

Our combination tools produce unrivaled toothing quality and of course offer high repeat accuracy during tool changeover. Along with backtapering, pocket milling and other operations can be integrated into our tools to avoid the need for additional set-ups. Let us advise you!

Discover the pocket milling process type.

Backtapering tool

For this narrow sliding sleeve with closely spaced backtapers, we have developed a backtapering tool with opposing indexable inserts. This version is also characterized by high toothing quality and precise, repeatable tool changeovers.

Discover the backtapering process type.

Pointing tool holder

This solution, developed and produced by us, makes it possible to perform the pointing process in a skiving machine with only one milling spindle, thereby ensuring an optimum cost-benefit ratio.

Discover the pointing process type.

Pointing tool

The particular feature of this task was that due to the component’s clamping situation, the pointing has to be applied to the rear side. Of course, our specialists have also developed an appropriate tool solution for this.

Discover the pointing process type.

External reaming tool

As a specialist for tool solutions, we offer both reaming inserts and complete tools for your task. The tool shown is equipped with three support plates and one reaming insert for reaming a cylindrical surface.

Discover the reaming process type.

Deburring tool

After gear skiving, a burr is created on the exit side of the machining process, which is usually difficult to deburr due to the component’s interfering contour. We have developed this tool solution especially for deburring these components.

Discover the deburring process type.