MADE FOR MASTERPIECES: ROTATIVE SYNCHRONOUS MACHINING

One tool for multiple processing steps.

Highly complex construction – to let you benefit from simplified use. The innovation in component production!

ANYTHING BUT OFF-THE-SHELF: CONVENTIONAL MACHINING

The standard with far-reaching optimization potential.

Even with long-established and proven tool solutions, cost and quality specifications demand permanent development and component production – the difference is in the detail.

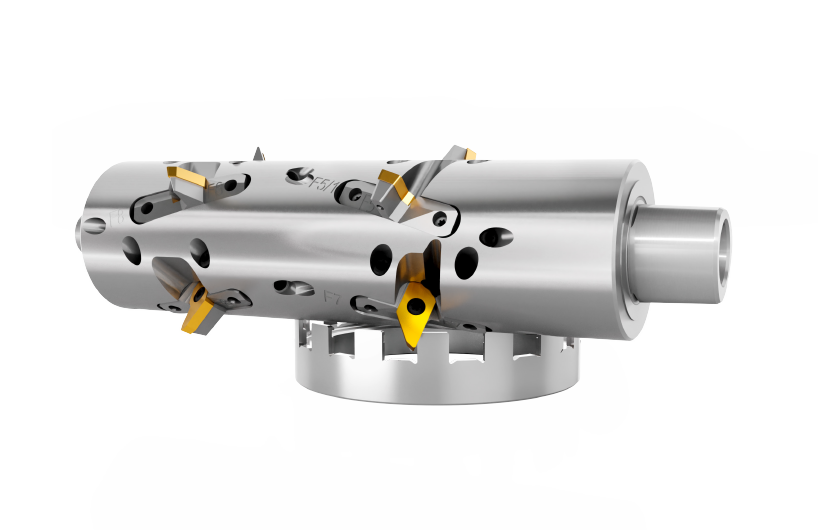

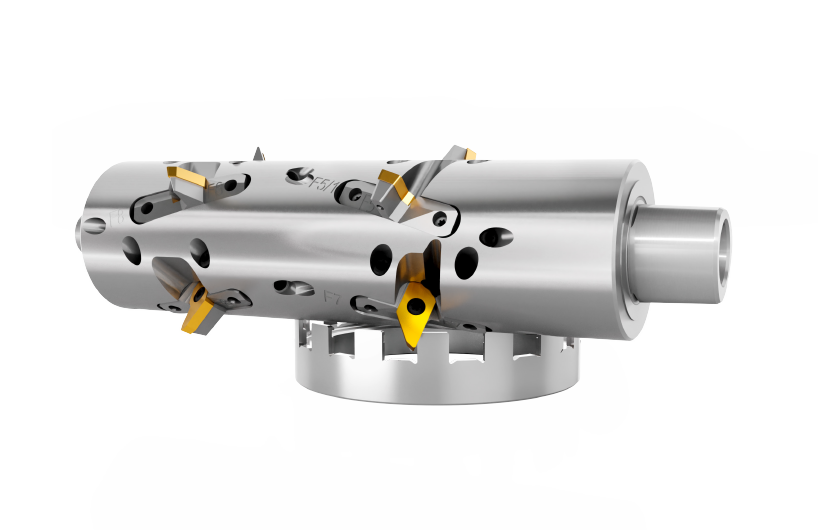

MADE FOR MASTERPIECES: ROTATIVE SYNCHRONOUS MACHINING

One tool for multiple processing steps.

Highly complex construction – to let you benefit from simplified use. The innovation in component production!

ANYTHING BUT OFF-THE-SHELF: CONVENTIONAL MACHINING

The standard with far-reaching optimization potential.

Even with long-established and proven tool solutions, cost and quality specifications demand permanent development and component production – the difference is in the detail.

Tailored machining tools for your individual requirements.

Tailored

machining tools for your individual requirements.

As a technological leader for all types of synchronous and conventional machining applications, we can develop and produce the ideal solution for highly efficient series production of your component. You are very welcome to contact us on a no-obligation basis and tell us about your requirements! On the basis of these specifications, our engineers will work in close coordination with practice-oriented technical experts to develop a tool solution that meets your needs down to the smallest detail. After successful testing we will deliver the tool to your site for first use, accompanied by an application engineer or designer if requested.

What if your requirements change? You know a call is all it takes!

Rotative synchronous machining

Rotative

synchronous machining

Our specialization benefits you.

In this process, the tool and workpiece move synchronously in relation to one another. These are processes in which the tool and workpiece shafts are connected with a fixed transmission ratio. This means that rotation-symmetrical cutouts can be efficiently achieved with a low rate of spacing errors, for example when milling a toothing system.

A wide variety of bodies recommend us on the grounds of this technology, using which we can empower you to produce components where conventional machining solutions reach their limits. By bringing together multiple processing steps in one tool solution, our combi-tools facilitate impressive savings of both time and money, while still consistently maintaining the highest level of quality. Through unrivaled changeover accuracy, as well as practically oriented coating and finishing for our indexable inserts tailored to your needs, downtime of your production machines is reduced to an absolute minimum. And our delivery service and reliability is renowned worldwide.

In summary: With our extensive experience in the area of combi-toools, services for process optimization, our own coating center and the unique accuracy of our indexable inserts, we are ideally equipped to respond to your requests. Find out more about the various options in terms of rotative synchronous machining.