SOLUTIONS FOR THE AUTOMOTIVE SECTOR.

The right precision tool for your perfect component.

If you and your customers refuse to compromise on quality, then we are speaking the same language! Our innovative and unique tool solutions enable you to produce new and challenging components as well as to optimize existing ones – always with the optimum cost-benefit analysis in mind.

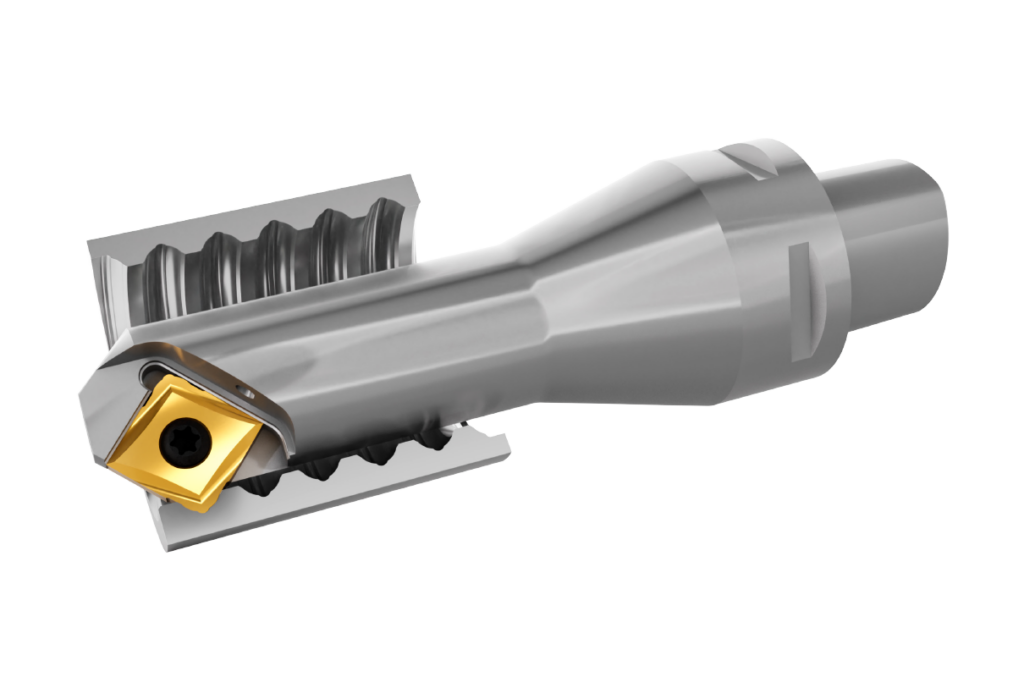

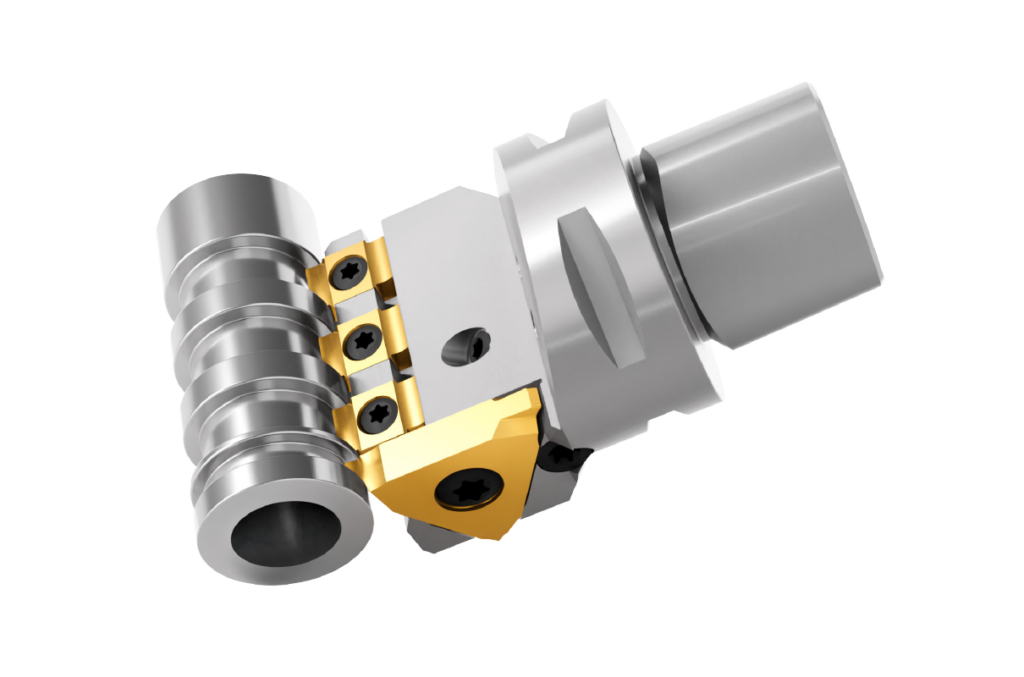

Thread-turning tool

When turning ball screws for steering nuts, the most precise tools are required. Combining our indexable inserts with our carrier tools is a guarantee for the very highest level of precision. We can also offer a vibration-absorbing version of the carrier tool if needed.

Discover the turning process type.

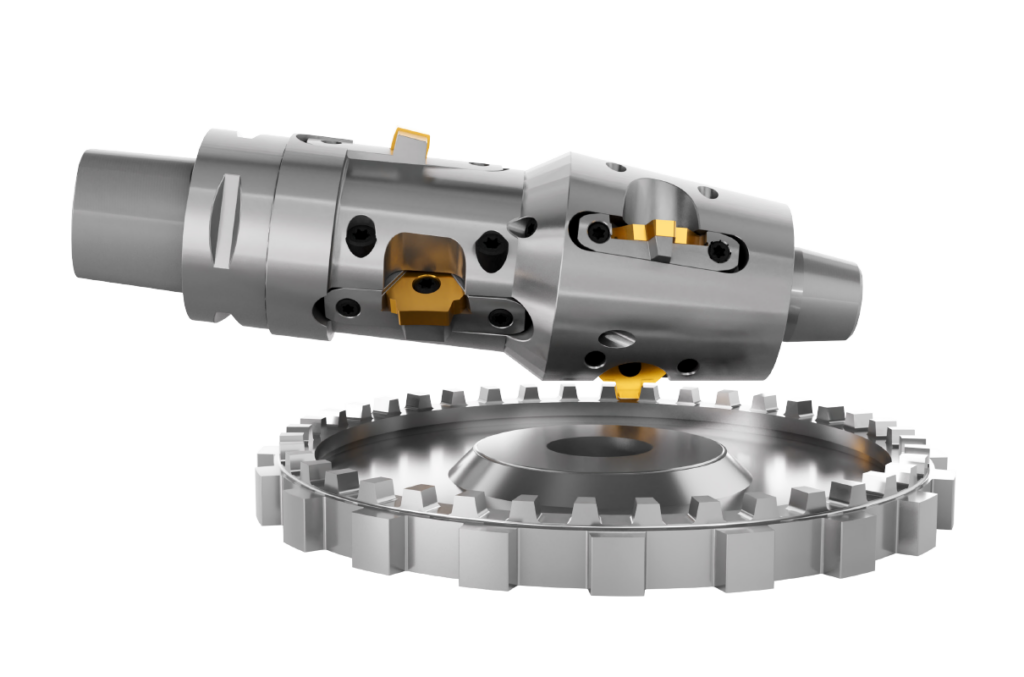

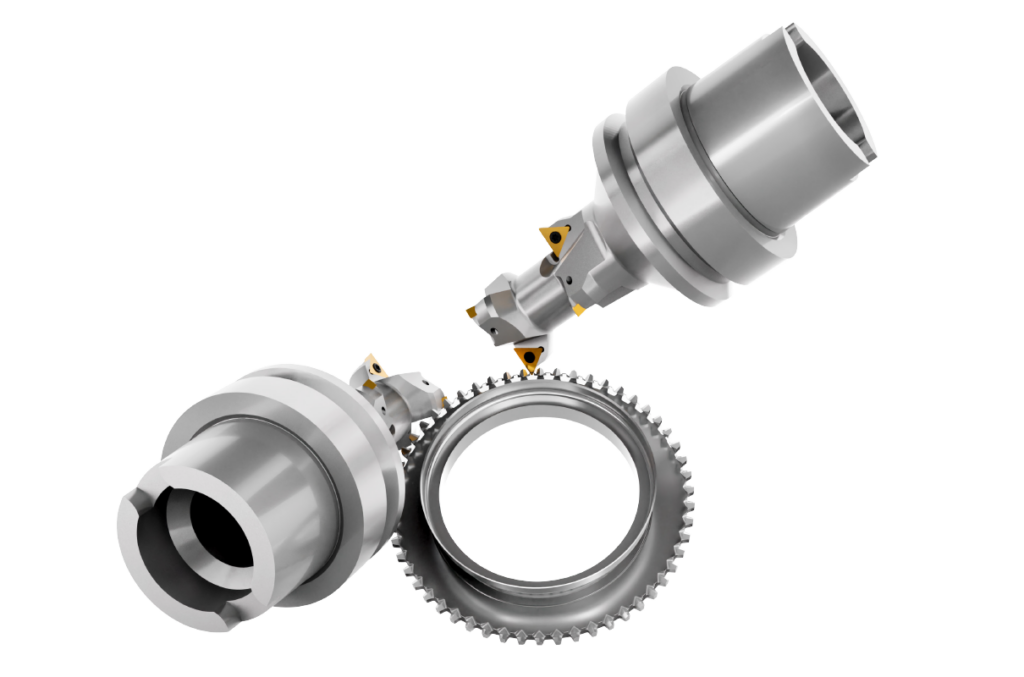

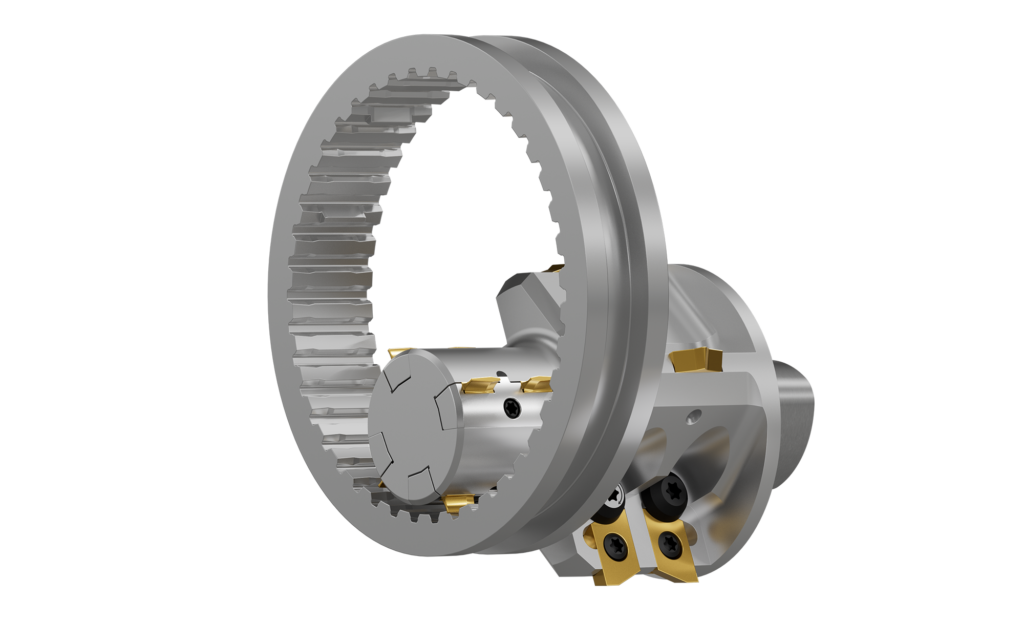

Impact tooth combi-tool

An example of the optimum solution for face and circumferential gearing. The circumferential gearing works with two pre-cutters and one finishing cutter. The face gearing sensor is processed by two finishing cutters. All milling cassettes can be adjusted both axially and radially.

Discover the face andcircumferential gearing process type.

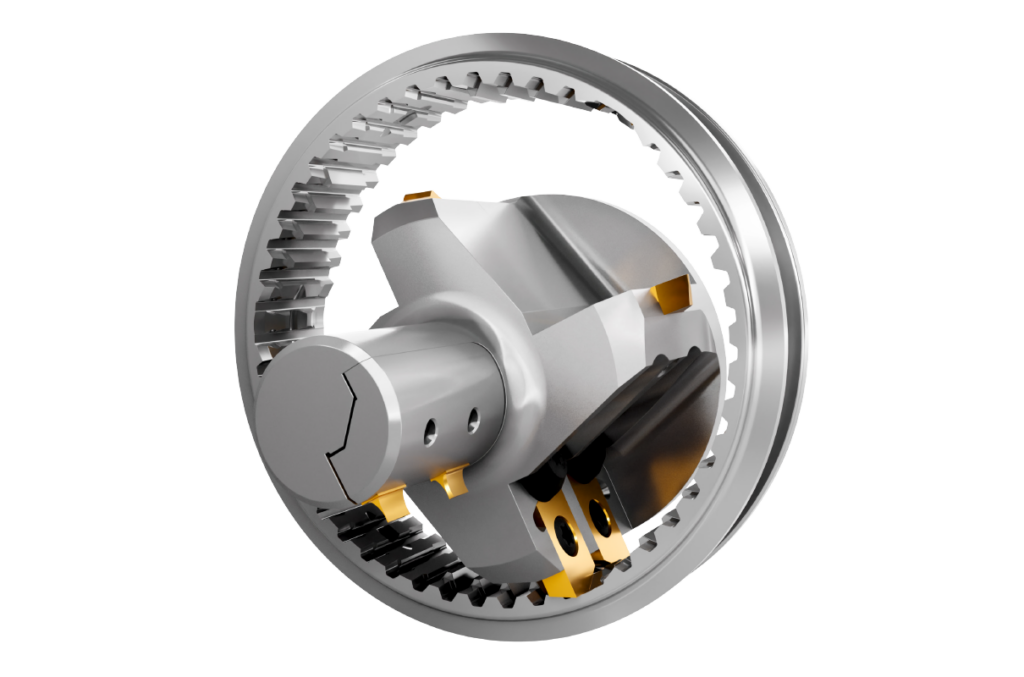

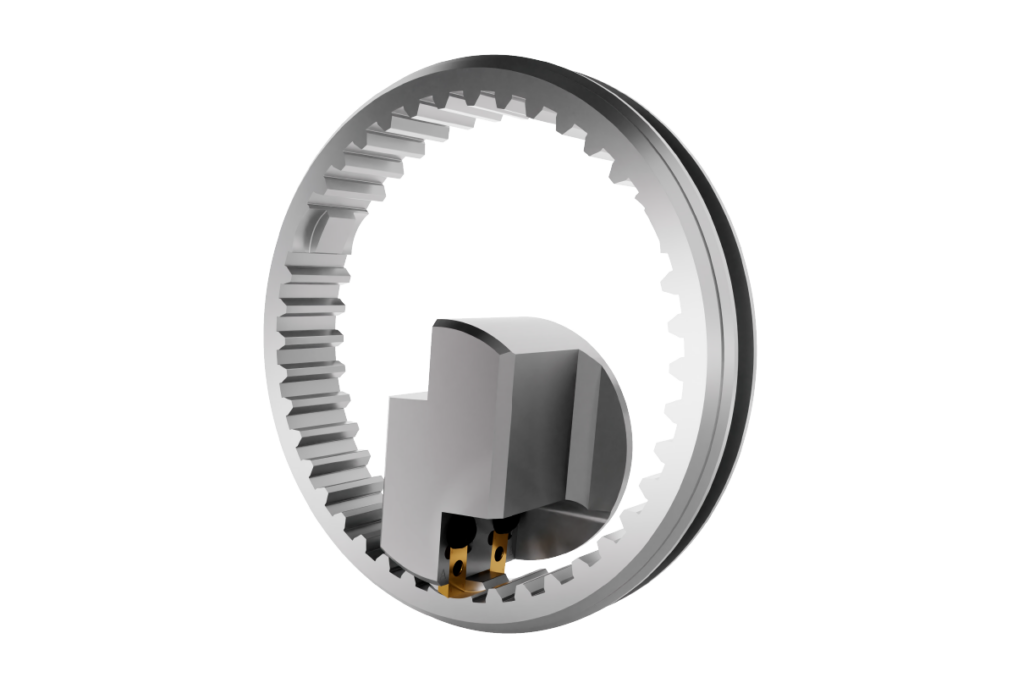

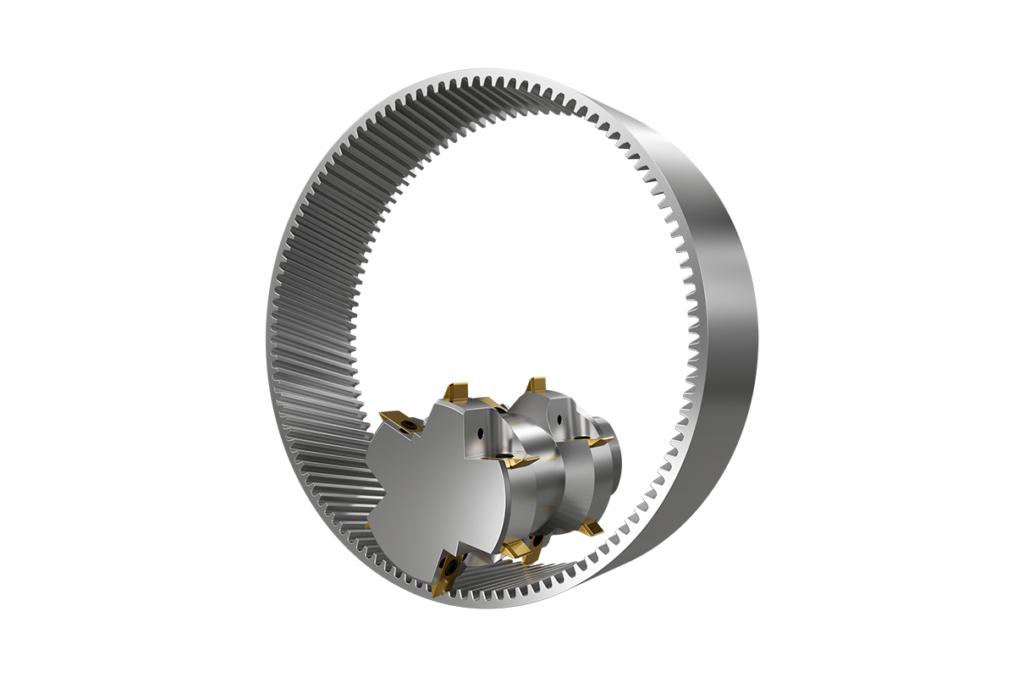

Impact tooth milling tool

In the field of small to medium tooth geometries, the use of insert milling cutters has decisive advantages over the relatively expensive hobs, which also require additional logistics for regrinding and coating. The tool costs are surprisingly moderate due to the mostly multiblade inserts.

Discover the face and circumferential gearing process type.

Rounding tool

Roundings can also be machined synchronously by rotation, depending on the component. A crucial advantage that results from our expertise: For this component, machining can be carried out using two finishing cutters, which considerably reduces machining time and therefore costs.

Discover the rounding process type.

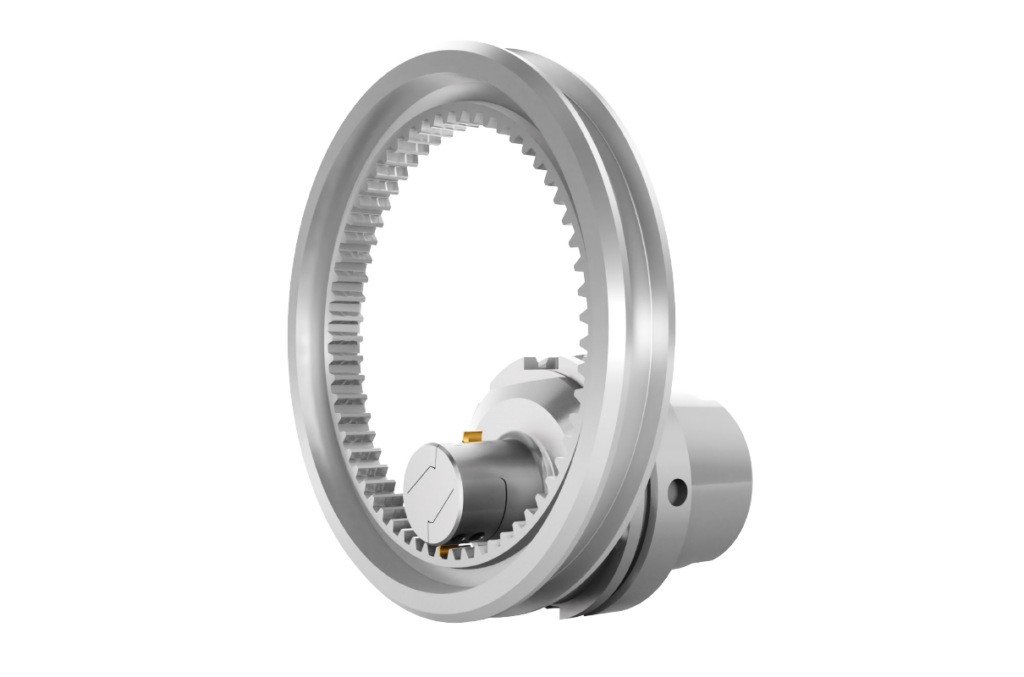

Sliding sleeve production combi-tool

Our combination tools produce unrivaled toothing quality and of course offer high repeat accuracy during tool changeover. Along with backtapering, pocket milling and other operations can be integrated into our tools to avoid the need for additional set-ups. Let us advise you!

Discover the pocket process type.

Milling tool

We are your expert partner in the development of milling tools for a wide range of applications and shapes. As an example, we would like to present a form milling cutter for the alternative production of trailer coupling ball heads on a processing center.

Discover the milling process type.

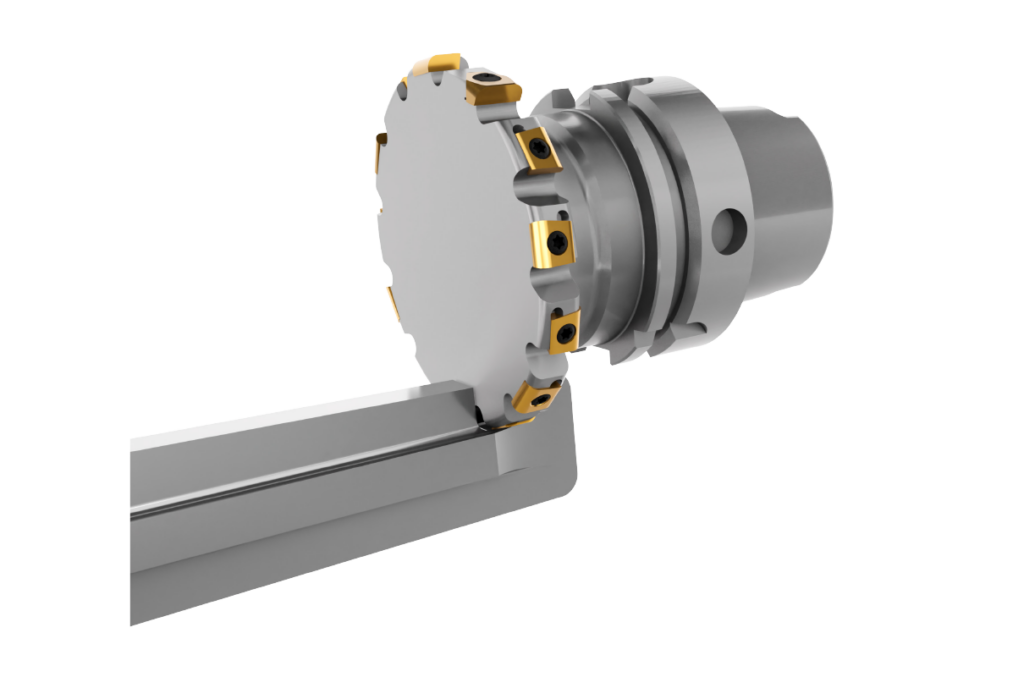

Slot milling tool

In order to meet a tight tolerance and a long tool life, we have designed a finished cutting insert with 12 pre-cutting inserts for this tool, which delivers unparalleled smoothness of running in production.

Discover the milling process type.

Backtapering tool

For this narrow sliding sleeve with closely spaced backtapers, we have developed a backtapering tool with opposing indexable inserts. This version is also characterized by high toothing quality and precise, repeatable tool changeovers.

Discover the backtapering process type.

Pointing tool holder

This solution, which has been developed and produced by us, makes it possible to perform the pointing process in a skiving machine with only one milling spindle, achieving an ideal cost-benefit ratio.

Discover the pointing process type.

Impact hob

A rotative process has led to significantly shorter cycle times when cutting crown gear teeth. Added to this is extremely high dimensional accuracy – delivered as standard by all tool solutions from our company.

Discover the face gearing process type.

Grooving tool

Our tool solution means the undercut can be produced with “just” one groove, which eliminates the need for time-consuming copy turning. In addition, the chip flow has been decisively improved by optimizing the chip removal stage. Details that make the difference.

Discover the turning process type.

Turning combi-holder

In the design we have developed, several grooves can be combined in one holder, achieving a significant reduction in machining time. Due to the precise manufacturing of the tools, even very tight tolerances can be effortlessly maintained.

Discover the turning process type.

Internal reaming tool

We of course also have solutions to suit your company for all special applications such as internal reaming of cones. As a representative example, let us present the fully adjustable tool with three reaming blades.

Discover the reaming process type.

Backtaper milling

Another great example of using a synchronous milling process is the formation of backtaper pockets on external gears. The tool is equipped with three finishing cutters, reducing the cycle time and resulting in associated high efficiency.

Discover the backtapering process type.

Chamfering tool

The tool has been designed to match the component, applying a defined chamfer with repeat accuracy and short cycle times.

Discover the chamfering process type.

Pointing tool

Several surfaces on one tooth can also be machined synchronously by rotation. Here, two surfaces are applied in one tool rotation, with corresponding benefits in terms of time and costs.

Discover the pointing process type.

Block tooth milling tool

In addition to innovative combination tools, we also offer individual tools for machining the block teeth. We achieve identically high levels of both angular and repeat accuracy with this solution.

Discover the block tooth millingprocess type.

Backtapering tool

Our combination tools produce unrivaled toothing quality and of course offer high repeat accuracy during tool changeover. Along with backtapering, pocket milling and other operations can be integrated into our tools to avoid the need for additional set-ups.

Discover the backtapering process type.

Backtapering tool

Depending on the component specifications, several cuts can also be implemented in one backtapering tool, for enhanced productivity.

Discover the backtapering process type.

Backtapering tool

Discover the multi-cut backtapering tool in combination with additional operations! Equipped with several cuts, it offers maximum efficiency in backtaper machining. Increase your productivity and get fantastic results.

Discover the backtapering process type.

Profile milling tool

Tailored profile milling machine with inserts for steel components. Unrivaled precision and durability. Perfect adaptation to your individual profile.

Discover the milling process type.

Deburring tool

After gear skiving, a burr is created on the exit side of the machining process, which is usually difficult to deburr due to the component’s interfering contour. We have developed this tool solution especially for deburring these components.

Discover the deburring process type.

Do you have questions?

I look forward to hearing from you.

Florian Heusch

Head of Sales