SOLUTIONS FOR THE FOOD INDUSTRY.

We deliver the ingredients for more efficiency in your production.

The recipe for successful and cost-efficient production of components is one sophisticated concept using our extremely high-quality combination tools that bring together several of your work processes in a single work step. These tasks are exactly to our taste. Give us a try!

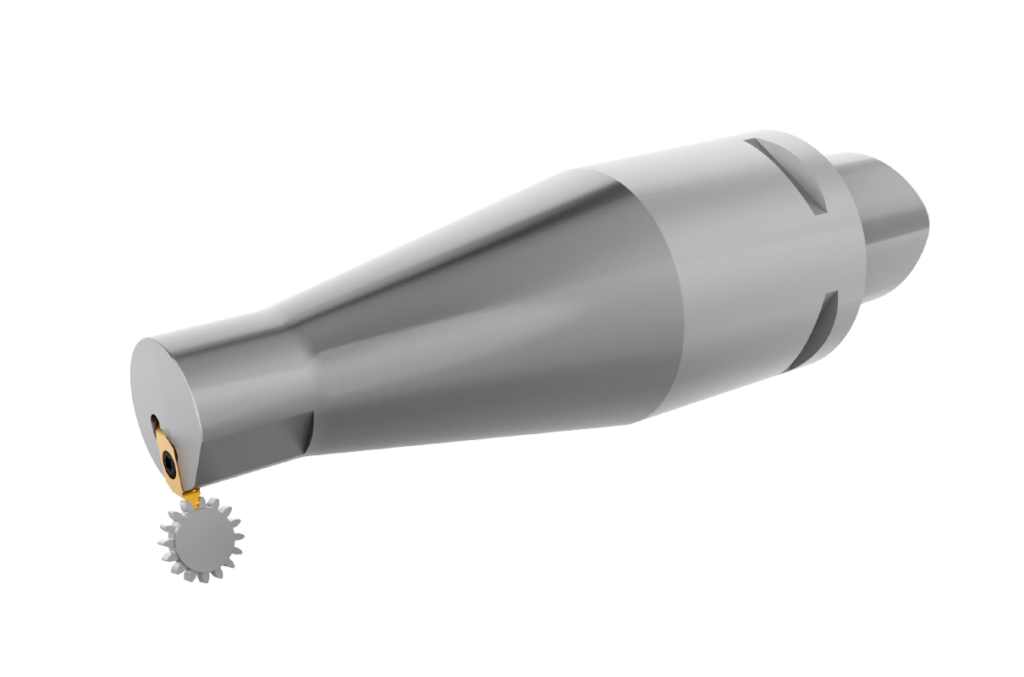

Impact tooth tool

Using this example, we can demonstrate to you that even the smallest involute toothings can produced rotatively on a synchronous basis. The sprocket diameter is just 14.6 mm. In this case only one finishing cutter is used for better variability, which means it is also possible to quickly retool for different profiles. An ideal solution for this requirement.

Discover the circumferential gearing and impact milling process type.

Disc milling tool

To fulfill the customer’s request for a fine-toothed disc milling machine that runs as quietly as possible, we have arranged the 22 inserts on this tool tangentially. The angle for the required profile has also been individually adjusted here. The multiblade indexable inserts result in highly economical operation.

Discover the milling process type.

Cassette milling tool

In designing rotative synchronous machining for coffee-grinding discs, the solution we developed has contributed to considerably increased efficiency in the production of face gearing in a machining center.

Discover the face gearing process type.