SOLUTIONS FOR MECHANICAL ENGINEERING.

A diverse industry with individual requirements.

Whichever of the huge range of process types you use to produce your components – whether conventional machining processes such as turning, milling and grooving or rotative synchronous processing – choosing tool solutions from Kristen + Görmann gives you access to significant advantages for your production. One aspect of this is increased output and therefore lower costs per component. Find out about other factors and get in touch with us.

Disc milling tool

Two individually designed disc milling cutters can be used to optimally mill the toothing on a rack in a single process. Using one disc milling cutter for the toothing and an additional disc milling cutter for the run-out at the ends of the toothing ensures extremely efficient production.

Discover the milling process type.

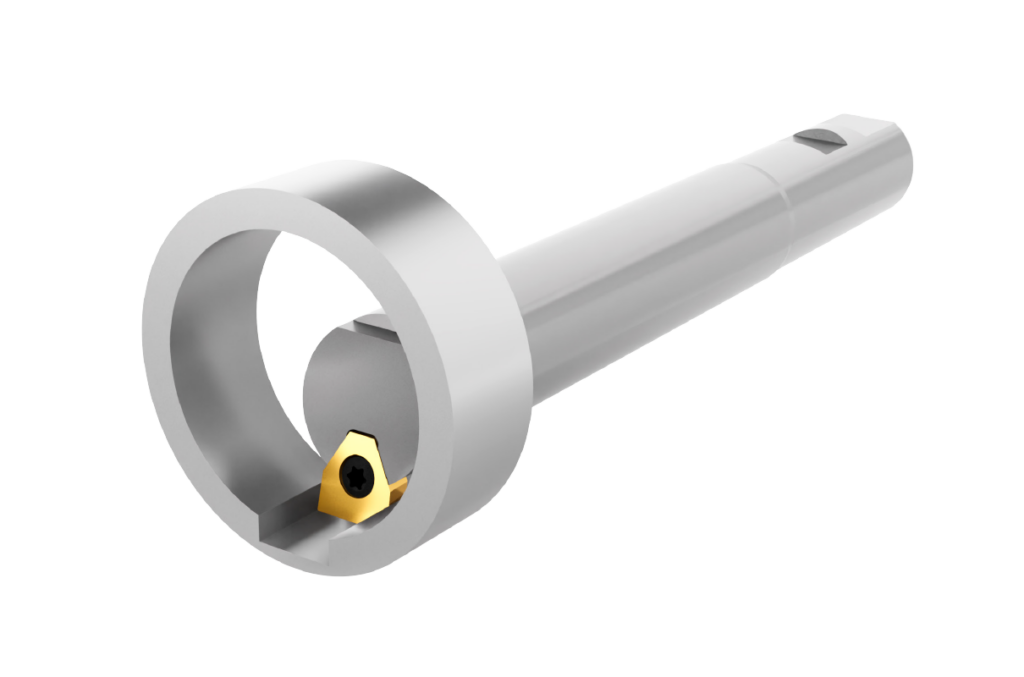

Combi turning tool

To produce a double thread much more effectively, we have integrated one insert per thread in each tool. The excellent repeatability of our inserts means that reliable production of the thread is now possible with a higher throughput – though of course always within the tolerances.

Discover the turning process type.

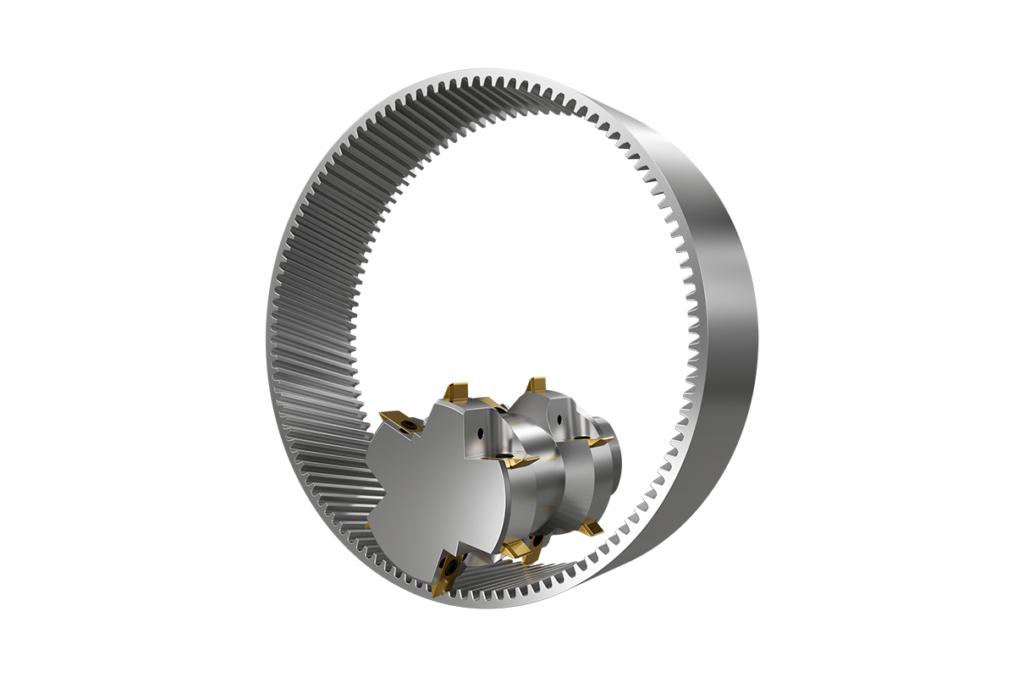

Impact tooth milling tool

As this component’s flanks run oriented on the center without a contour path, the face gearing is produced via two cuts. Due to its use in modern precision transmissions, the tightest tolerances must be complied with here.

Discover the face gearing process type.

Grooving tool

Based on your requirements and depending on your preferred profile, multiple grooves can also be formed with just one indexable insert. In this way our highly precise tools significantly reduce the machining times previously required for classic portfolio solutions.

Discover the turning process type.

Turning tool

If you need tools for copy turning, we are the right point of contact for an individualized offer. With Kristen + Görmann you benefit from the fact that we can adapt our solutions to suit your task, in terms of both the step and the coating.

Discover the turning process type.

Slotting tool

If dimensions for longitudinal grooves need to be complied with and this makes it impossible to use standard tools, or if other parameters necessitate a particular solution, our slotting tools can be adjusted to your individual preferences.

These tools are also used in our internal process for driver slot production on our disc cutters. Of course, we can also implement your requirements for the carriers.

Discover the slotting process type.

Slotting tool

As you would expect, at Kristen + Görmann we can of course also realize special shapes, for instance with this internal spline featuring multi-stage cutting sequences. We look forward to hearing about your requirements!

Discover the slotting process type.

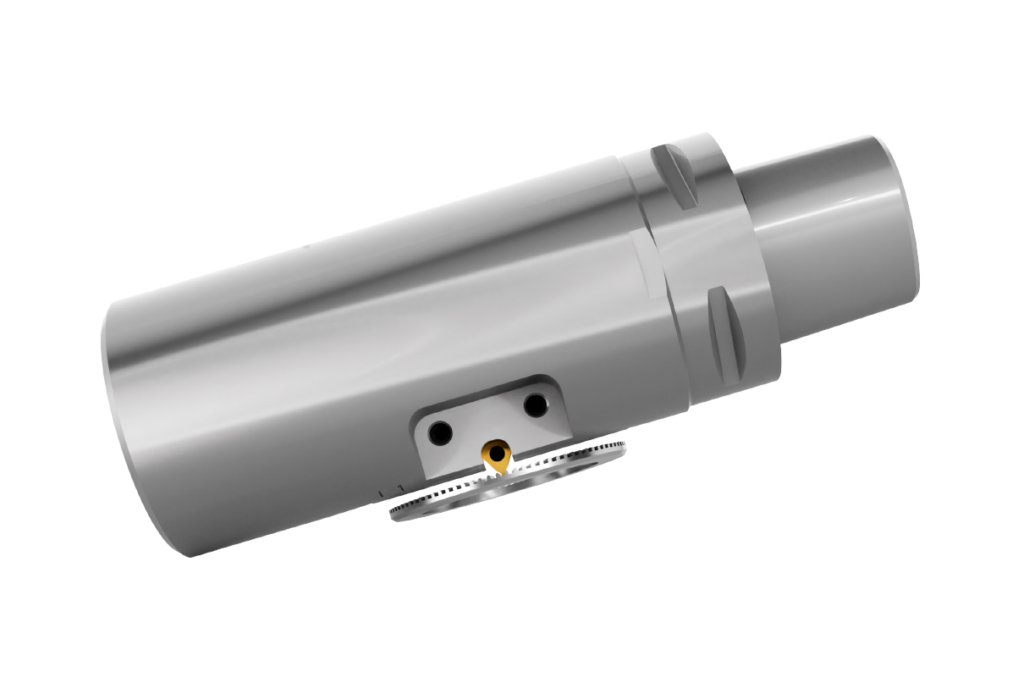

Deburring tool

As an additional feature, this special deburring tool has inserts for both sides of the component. After shifting the tool and changing the direction of rotation, the second side can also be reproducibly deburred by means of a rotative synchronous process. Discover the deburring process type.Profile milling tool

Tailored profile milling machine with inserts for steel components. Unrivaled precision and durability. Perfect adaptation to your individual profile.

Discover the milling process type.

Deburring tool

After gear skiving, a burr is created on the exit side of the machining process, which is usually difficult to deburr due to the component’s interfering contour. We have developed this tool solution especially for deburring these components.

Discover the deburring process type.